Machining Services

At DVSF, our machining services are a cornerstone of our comprehensive metalwork capabilities.

Combining precision, versatility, and innovation, we provide high-quality machining solutions that support fabrication, welding, and pipework, delivering a full turnkey solution for businesses across multiple industries.

Our facility is equipped with advanced CNC and manual machines, including 4 manual lathes, 2 milling machines and 1 CNC lathe enabling us to produce intricate components accurately and efficiently.

Whether turning, milling, drilling, or executing complex CNC programmes, our skilled machinists deliver reliable, high-specification results every time.

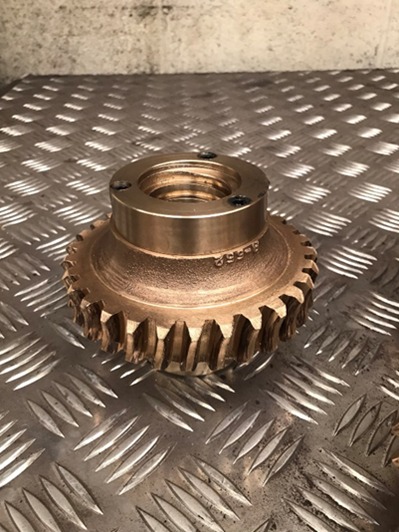

Products & Components We Manufacture

- Wheels, pulleys, shafts, and rollers

- Gears and sprockets

- Shrink and expansion fittings

- Bespoke precision components for industrial and commercial applications

Our expertise extends across multiple materials:

- Mild steel

- Stainless steel

- Aluminium

- Brass

- Nylon

This versatility allows us to provide mechanical, structural, and specialist solutions tailored to your application.

Advanced Equipment & Wide Range of Services

CNC & Manual Milling and Turning

We produce precise, repeatable components using both CNC and manual machinery. Ideal for shafts, housings, brackets, and high-tolerance parts needed across manufacturing and engineering sectors.

Drilling, Tapping, Reaming & Boring

We deliver accurate hole processing for new and existing components, including threading, bore finishing, and hole enlargement to support fabrication, assembly, and engineering work.

Bespoke & Complex Manual Machining

For custom shapes, one-off parts, or components requiring hands-on expertise, our manual machining offers flexibility and accuracy where CNC programming is not practical.

Surface Finishing & Tight-Tolerance Machining

Our finishing processes ensure smooth surfaces, accurate fits, and consistent tolerances, making them ideal for high-precision assemblies and critical mechanical applications.

Component Replication & Reverse Engineering

We recreate damaged, worn, or discontinued components to original or improved specifications. Perfect for maintenance, repairs, and older machinery where replacements are unavailable.

Prototype Development & One-Off Components

We produce single components and prototypes quickly and accurately, supporting R&D, product development, and customised machinery requirements.

Fabrication-Ready Machined Parts

We prepare parts for welding and fabrication with accurate fits, bevels, and joint features to ensure smooth assembly and stronger final structures.

Why Choose DVSF for Machining?

Versatile Machining Capabilities

4 manual lathes, 2 milling machines, and a CNC lathe for varied projects.

High-Precision Results

Accurate machining with tight tolerances for demanding applications.

Experienced Machinists

Skilled experts ensuring quality, consistency, and technical reliability.

Custom Component Production

Parts tailored exactly to your specifications and performance needs.

Integrated Metalwork Services

Machining combined with fabrication and welding for end-to-end solutions.

Reliable Turnaround Times

Consistent delivery schedules that keep your projects moving.